With the continuous development of the construction industry and technological advancement, the design and installation of piping systems have become more and more important. As one of the best modern piping systems, PPR pipe fittings are changing the traditional water pipe connection with their excellent performance.

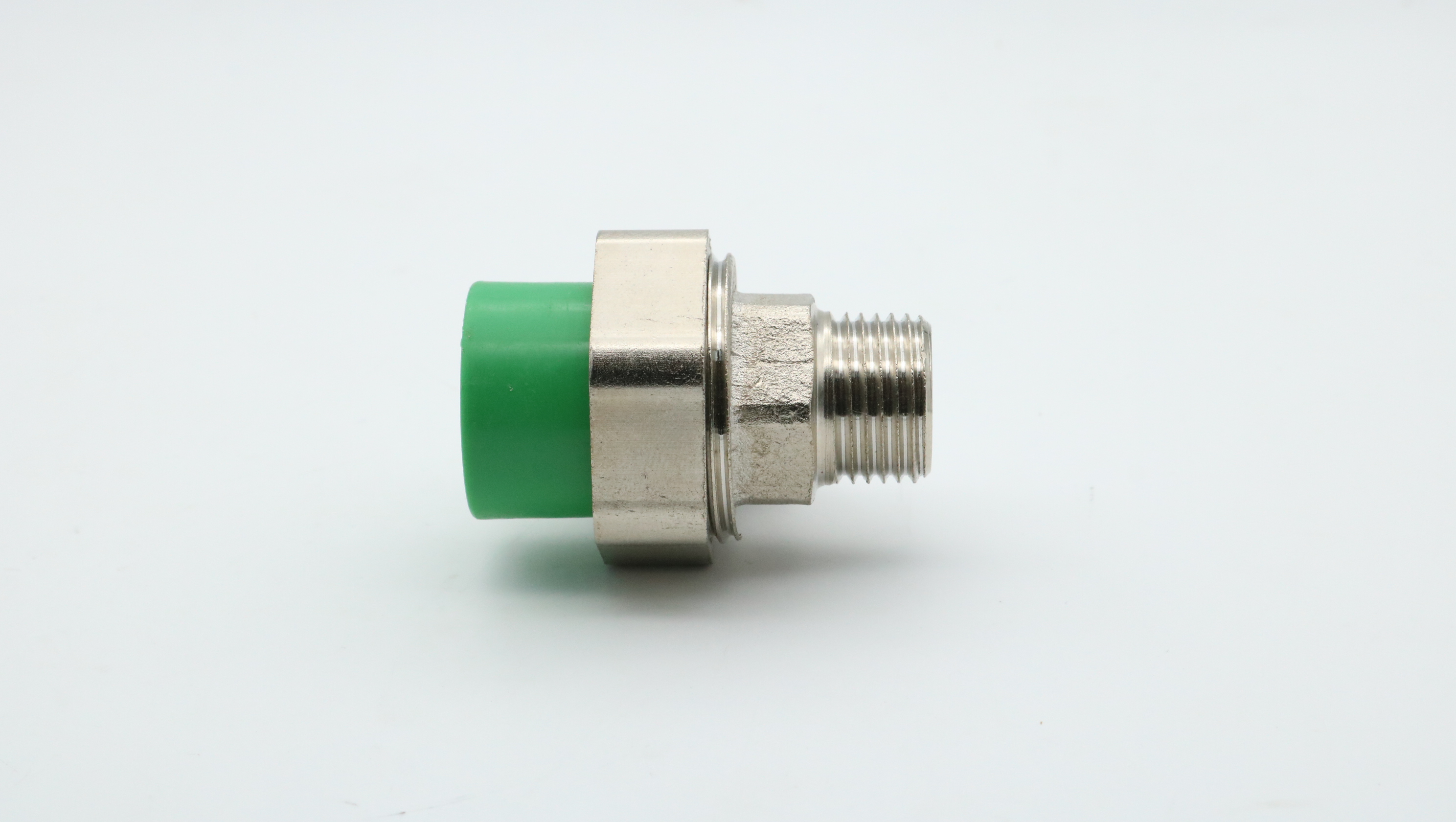

Why do more and more professionals choose to use PPR pipe transition male connectors? The answer lies in its high reliability and durability. Compared with traditional metal pipe fittings, PPR pipe fittings have stronger corrosion resistance and will not rust over time. It also has excellent heat resistance and compressive strength, which is very suitable for home decoration and complex industrial project environment.

The high quality is inseparable from advanced technology and strict production standards. Our PPR fittings are made of food-grade raw materials to ensure the safety and health of the product. At the same time, the pipe fittings processed by precision mold forming process have regular shape and smooth surface, which reduces water flow resistance and improves work efficiency.

Highlights:

- Wide temperature range (-20 ℃ ~ 110 ℃)

- Strong pressure bearing capacity (can withstand pressure up to 2.5MPa)

- Strong sealing performance to prevent water leakage

whether it is residential kitchen bathroom or large factory equipment supporting water supply pipeline construction, PPR pipe fittings can be competent. For example, in the home environment, it can be used for the transformation and upgrading of hot and cold water supply networks; in the commercial field, it is often used to build air-conditioning cooling circulation waterways or fire sprinklers.

How to determine the correct specifications? The first thing to consider is the actual application scenarios required by the size of the working pressure and medium temperature conditions and other factors, and accordingly consult the relevant parameter table to select the appropriate model of the product. Secondly, pay attention to whether the size of the interface at both ends matches the standard caliber value of the object to be connected.

For those who are first exposed to such tools, the correct implementation of the installation may seem a bit complicated. In fact, as long as the following steps can be easily done:

the first step: prepare the required materials including PPR pipe, special heater and other auxiliary accessories.

the second step: insert the two pipe ends to be spliced into the corresponding female mouth positions respectively until the bottom stops.

the third step: after starting the machine set time, wait for the designated period to take out to form a solid integrated structure.

During the construction period, we will inevitably encounter some difficult problems. What should we do? Don't worry! The following are some common questions and their solutions:

Q: What should I do if I find bubbles in the welding part?

A: It is probably caused by insufficient heating. Please extend the heating time appropriately and try again.

Q: What is the cause of slight leakage after installation?

A: it may be caused by local deformation caused by excessive force. it is recommended to disassemble it to check whether there is any damage and then assemble it back according to the specified force.

Finally, it is worth mentioning that with the increasing awareness of energy conservation and emission reduction worldwide, the selection of green building materials has become a general trend. The PPR pipe fitting fits this concept-because it emits almost no pollutants throughout the life cycle and has a very high recycling rate, which can be regarded as a model for future sustainable development.