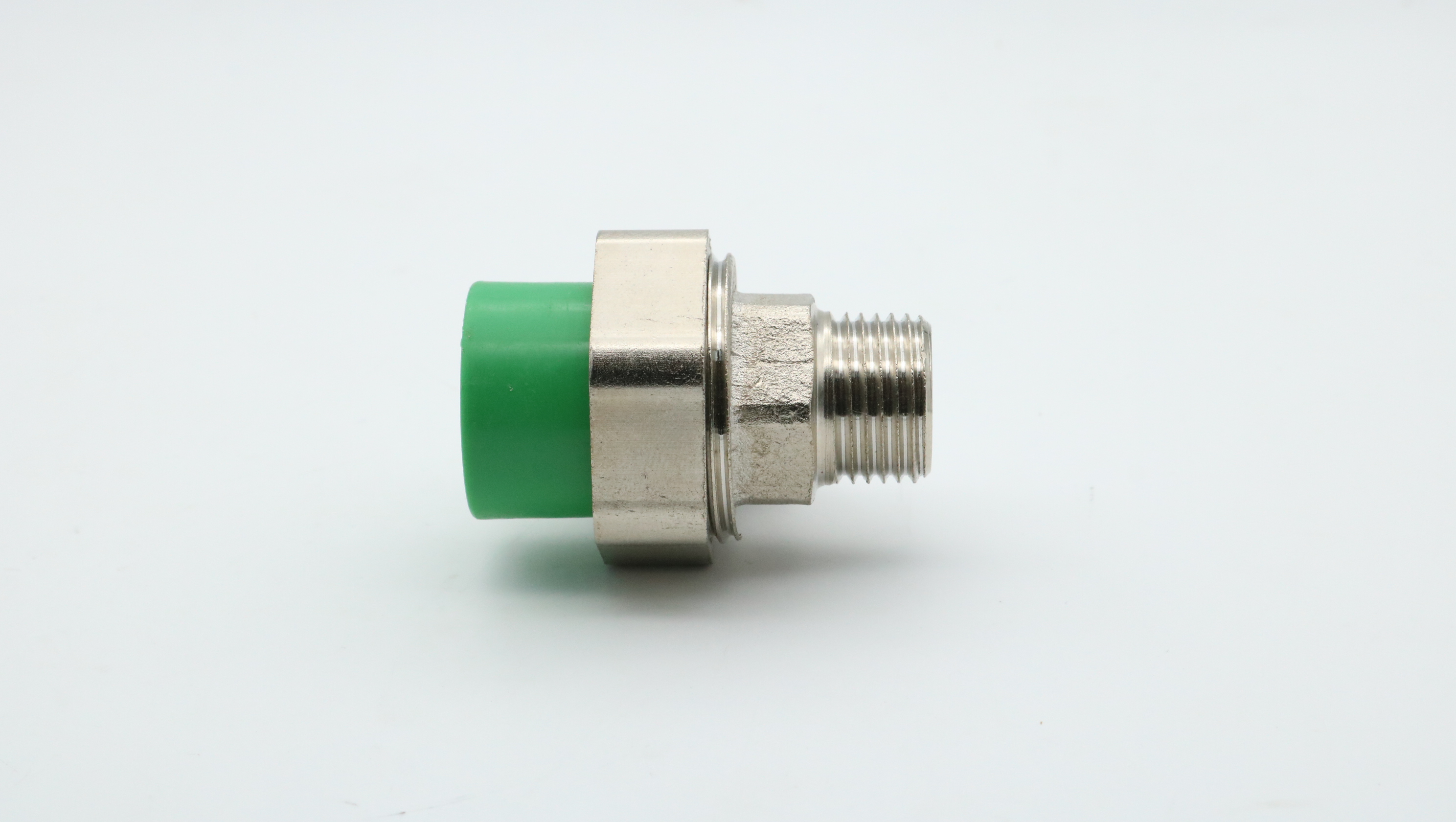

Among many types of pipe fittings, PPR pipe fitting transition male fittings stand out for their excellent durability and reliability. This product is made of high quality polypropylene random copolymer material (PP-R), which has excellent chemical stability, corrosion resistance and long service life. Even in extreme environments, such as high-rise building water supply systems, the joint can still maintain a stable working state.

Practical applications have proved that this high-performance connection component can not only significantly improve the user experience, but also greatly reduce the cost of subsequent maintenance. Due to the use of precision mold forming technology and automated production equipment, each part has reached a very high manufacturing accuracy standard, ensuring zero failure rate in long-term operation.

Solving the compatibility problem between different diameter specifications and materials is one of the challenges faced by many engineering projects. However, with a unique design concept and technological innovation, the PPR pipe transition male connector successfully achieved this goal. Whether you need to connect PVC drainage pipes, metal copper pipes or stainless steel water supply pipes, you can find the right solution here.

A successful case is that in a large shopping mall renovation project, the construction team used multiple types of PPR transition male connectors to complete the complex pipe network laying work. The results show that these joints are not only easy and quick to install, but also tightly connected, and there is no water leakage at all. This fully demonstrates their strong ability to respond to diverse needs.

In order to make the entire assembly process easier, engineers have made great efforts. From the initial drawing to the final practical instruction manual, every step has been repeatedly refined and improved. Especially in the dimensional accuracy control, through the introduction of advanced CNC machine tool equipment to ensure a high degree of consistency of all key parts; and in the interface part is added a special reinforcement process to enhance the mechanical strength.

In addition, a variety of installation methods, including hot melt welding, have also been fully introduced. Users can flexibly choose the most suitable operation mode according to the actual situation, and easily get started with the help of supporting professional tools. Both beginners and senior technicians can quickly grasp the key points, thus greatly improving work efficiency and shortening the schedule.

Enterprises are well aware of the great responsibility, so from beginning to end will be "quality first" as the first principle throughout. First of all, the selection of raw materials is extremely strict-only products from well-known suppliers in the industry are selected and put into use after multiple rounds of screening and inspection; secondly, the production process is strictly implemented in accordance with international standards to ensure that each finished product has the highest level Protective performance; finally, a series of strict tests and verifications must be accepted before leaving the factory, and only those who fully meet the standards are allowed to enter the market circulation link.

It is based on the above measures that each PPR pipe fitting entering the market can withstand the test of time and become a brand representative trusted by users. This also reflects the company in the pursuit of economic benefits at the same time do not forget the spirit of social responsibility.

With the increasing public awareness of environmental protection, "green GDP" has become a topic of common concern in all walks of life. For this reason, the R & D personnel specially upgraded the existing products-the new formula does not contain any harmful substances, especially heavy metal lead, which fundamentally eliminates the risk of secondary pollution; at the same time, the streamlined appearance after optimization looks more beautiful and generous, and more importantly, it effectively reduces the probability of energy loss during transportation.

Compared with other competitors on the market, our PPR fittings undoubtedly occupy a clear advantage in the transition joint. It is not only an ideal choice in line with the development trend of contemporary society, but also represents an important milestone in the future development direction of the industry. Let us work together to create a better tomorrow!

The success of PPR fittings has been witnessed by countless real customer feedback. Some customers are amazed: "It has been very strong and durable for so many years", and many owners specifically mentioned its excellent compression resistance and sealing effect. "Don't worry about water leakage anymore!" Such a voice is heard. These are the root causes of the brand's long-term prosperity.