Efficient connection, safe and worry-free: the core value of PPR pipe fitting transition male connector

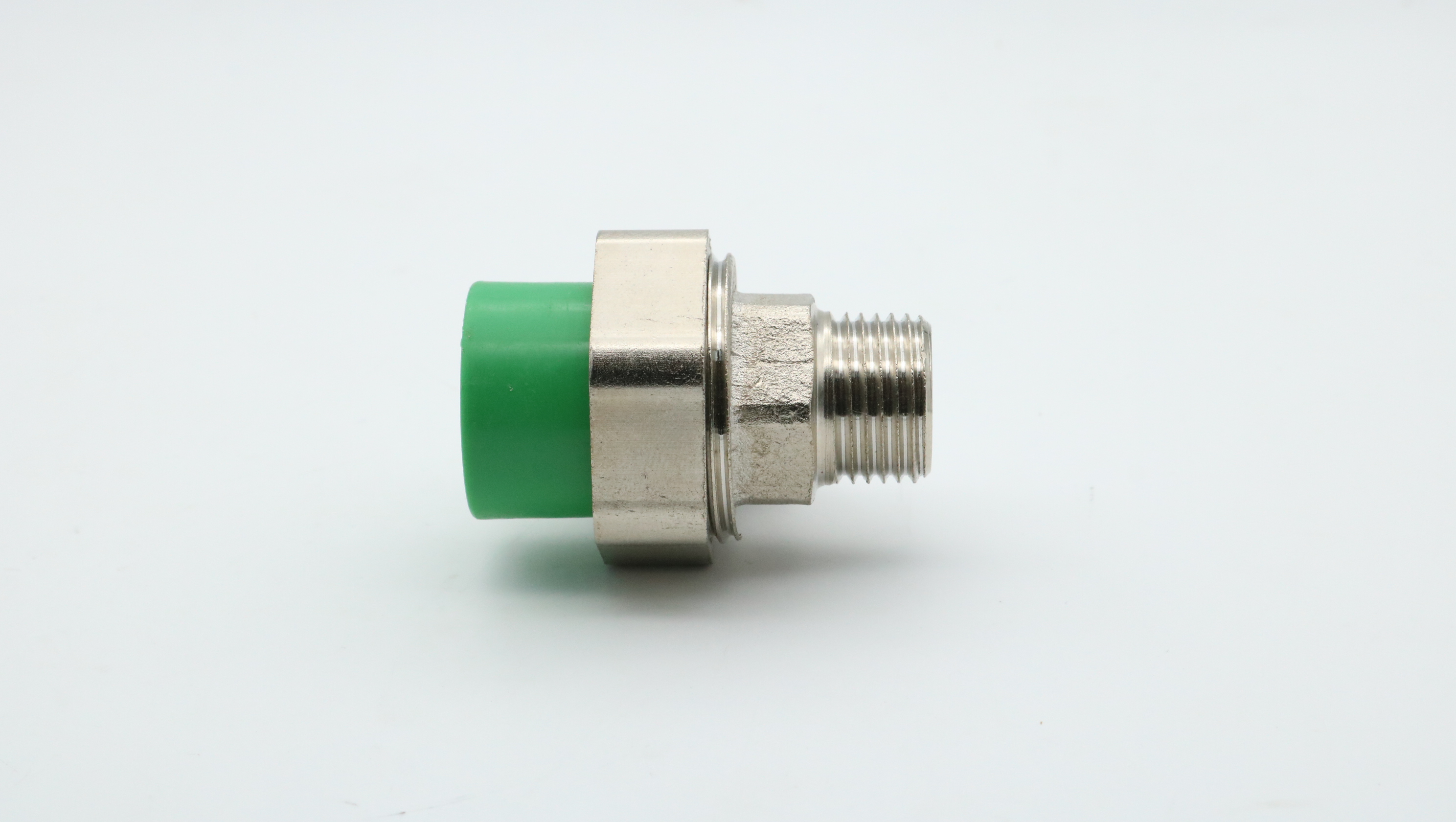

In many pipeline engineering projects, PPR pipe fitting transition male connector has gradually emerged with its excellent performance. The reason why this product is popular is mainly due to its deep accumulation and innovative design in the field of materials science.

From a microscopic point of view, PPR (triple polypropylene), as a new type of plastic material, has excellent mechanical properties and chemical stability. This allows the transition male connector not only to withstand higher temperatures and pressures, but also has excellent corrosion resistance. Even in the face of complex and changeable use environment, it can always maintain a stable operating state.

In addition, the product has very good sealing performance and can effectively prevent water leakage. Whether it is in cold water or hot water delivery system, it can provide reliable protection, so that users can rest assured to use.

Breaking the boundaries of tradition: revolutionary changes brought about by innovative design

Compared with the common common pipe fittings on the market, the PPR pipe fitting transition male joint has obvious technical advantages. First, a number of improvements have been made in terms of temperature resistance and compression resistance. It can withstand high temperatures up to 95°C or more without deformation, and the maximum pressure can reach 1.6MPa or more, far exceeding the general standard requirements.

Secondly, a unique internal and external thread structure design is adopted, which greatly improves the tightness and firmness of the interface. This ingenious design not only enhances the overall safety factor, but also extends the service life and reduces the frequency of maintenance.

Finally, it is worth mentioning that its dimensional accuracy is very high, and the error is controlled within the micron level, ensuring that the docking between each pipe is accurate.

Simplify the process: make installation easier

For the construction company, time is money. Therefore, how to shorten the construction period has become a common concern. PPR pipe transition male joint in this regard made a good demonstration.

Due to the hot-melt welding process for connection, the entire process takes only a few minutes to complete the assembly of a pipe. Compared with the traditional flange or ferrule joint, this method is not only much faster, but also does not require additional tools, which greatly reduces the labor cost.

More importantly, there is almost no waste residue during on-site installation, keeping the construction site clean and tidy, and further improving operation efficiency.

Adapt to multiple occasions: a wide range of applications

whether it is the laying of the tap water pipe network in the newly-built residential area or the upgrading of the heating system in the old office building, the PPR pipe fitting transition male connector can be competent for this important task. It can be tailored to specific project needs, flexible response to different types of construction projects.

Especially in some special fields, such as the purification of air conditioning and ventilation in the operating room of the hospital, and the construction of sanitary water pipelines in food processing plants, this product also performs well. This is because its material itself does not contain heavy metal ions and other harmful substances, in line with strict food safety and medical industry norms.

In short, with a wide range of compatibility and a high level of specialization, PPR pipe transition male joints have become an indispensable part of modern architecture.

Easy maintenance, long life: reduce later operating costs

In addition to the reasonable purchase price in the early stage, in the long run, PPR pipe fittings transition male joints can also bring more economic benefits to users. On the one hand, because of its excellent quality, there is little failure; on the other hand, it benefits from simple maintenance methods.

Periodically checking each node for looseness or leakage is the only necessary step, and there are no other complex procedures. If you encounter special circumstances need to replace parts, you can quickly find the matching model, and restore normal use in time.

Not only that, the manufacturer will also provide a complete after-sales service system as support, including but not limited to a series of measures such as technical support hotline to answer questions, technical personnel on-site maintenance guidance, etc., to fully protect the legitimate rights and interests of customers from damage.

Environmental Protection and Energy Conservation: Contributing to Sustainable Development

With the increasing awareness of environmental protection, all walks of life are actively exploring the road of green development. PPR fittings are no exception on transition male joints.

During production