When Water Meets Precision Engineering: Redefining the Art of Pipe Connections

Every morning begins with the turn of a tap—the rush of water that powers your coffee maker, fills your shower, or starts the dishwasher. Behind these everyday moments lies an intricate network of pipes and connections working silently to deliver clean, consistent flow. At the heart of this system are the connectors—small yet critical components that determine efficiency, safety, and longevity. Among them, the PPR Pipe Fittings Transition Male Union has emerged as a quiet hero in both homes and high-rises alike.

In residential kitchens and sprawling commercial complexes, where water pressure fluctuates and temperatures vary, a reliable joint isn’t just convenient—it’s essential. Traditional materials often struggle under such demands, but modern engineering has delivered a superior alternative. The transition male union bridges different piping systems with unmatched durability, ensuring that what happens behind the walls stays out of mind—for decades.

Why Traditional Fittings Are Being Replaced: A Quiet Materials Revolution

For years, copper, galvanized steel, and PVC dominated plumbing installations. Yet each comes with compromises. Metals corrode over time, especially when exposed to hard water or fluctuating pH levels. PVC becomes brittle under UV light and suffers from significant thermal expansion, leading to stress fractures. These issues translate into leaks, costly repairs, and inconsistent performance.

Consider a mid-rise apartment building where tenants complain about low pressure every winter. Investigation reveals micro-cracks in PVC joints caused by repeated heating and cooling cycles. In contrast, PPR (polypropylene random copolymer) handles temperature swings from 0°C to 95°C without deformation. Its near-zero thermal conductivity reduces condensation risks and energy loss—making it ideal for hot water lines and radiant heating systems.

Anatomy of a Perfect Joint: The Design Intelligence Behind the Transition Male Union

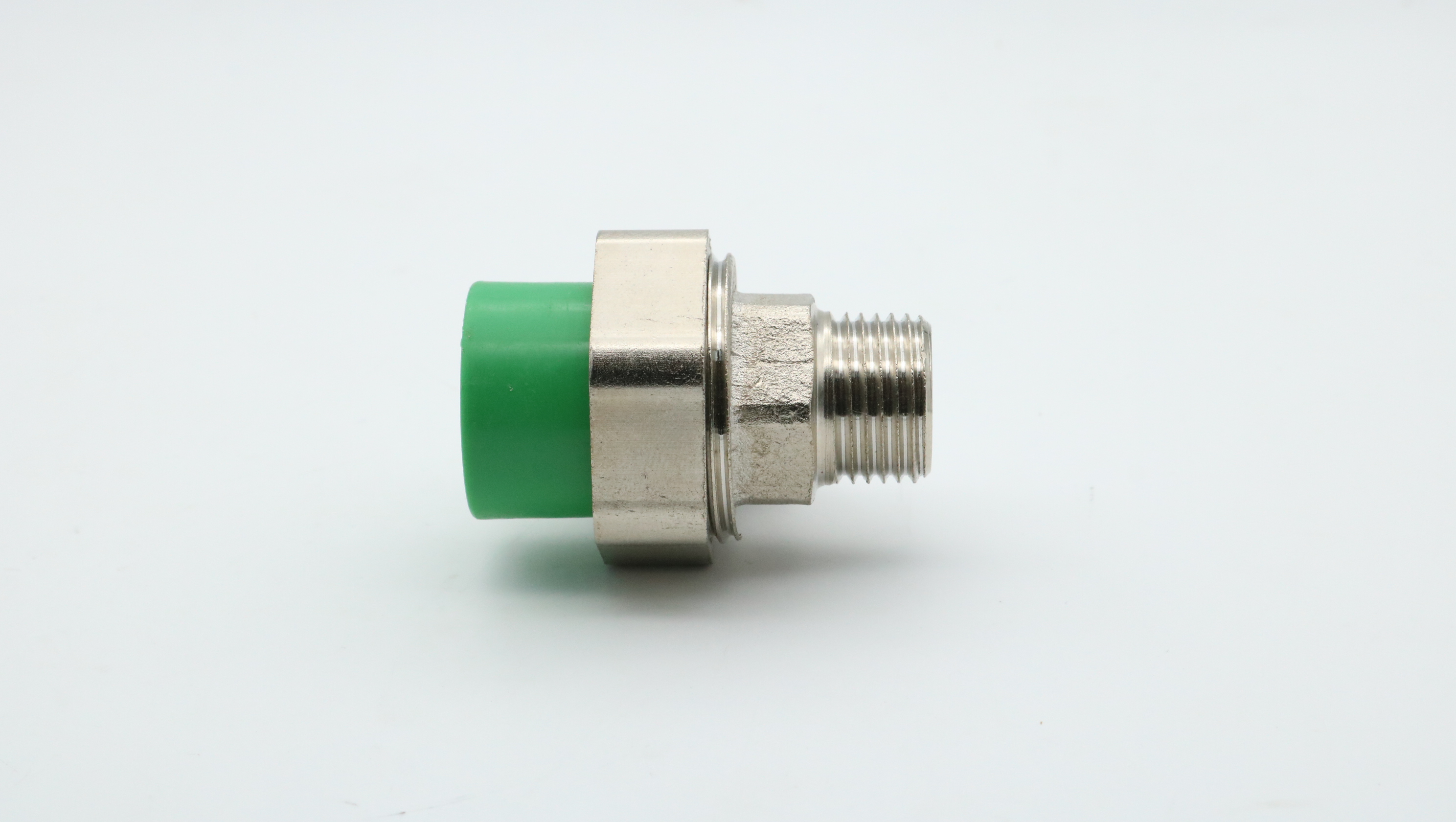

The brilliance of the PPR Transition Male Union lies in its thoughtful structure. One end features a socket designed for heat fusion with PPR piping, creating a monolithic bond stronger than the pipe itself. The other end integrates a threaded male connector, allowing easy attachment to metal or composite systems—a crucial advantage during retrofits or hybrid installations.

Between these two zones is a reinforced transition section engineered to absorb mechanical stress and prevent torque transfer. Constructed from high-purity homopolymer polypropylene, the fitting balances rigidity and flexibility, resisting both impact and creep deformation. Most importantly, the sealing mechanism relies on the molecular fusion of the heat-welded joint, eliminating rubber gaskets or O-rings that degrade over time. This is not just a connection—it’s a permanent integration.

From Homes to High-Rises: Versatility Across Applications

Whether renovating a century-old townhouse or commissioning a new wellness center, the Transition Male Union adapts effortlessly. In home upgrades, it enables plumbers to connect modern PPR tubing directly to existing threaded steel or brass fixtures—minimizing wall damage and downtime. For large-scale developments, standardized dimensions ensure compatibility across crews and contractors, streamlining inspections and reducing errors.

Its resilience shines in demanding environments like swimming pools, spas, and geothermal systems, where chlorine exposure and constant moisture accelerate material fatigue. Unlike metallic fittings that pit or scale, PPR remains inert, maintaining smooth internal surfaces that resist biofilm buildup and maintain flow efficiency over decades.

The Installer’s Secret Weapon: Faster, Cleaner, More Reliable

Professionals appreciate tools that save time while reducing risk. With the PPR Transition Male Union, the heat fusion process takes seconds and offers generous tolerance for alignment. Once cooled, the joint achieves full strength and pressure rating—no waiting for adhesives to cure or threads to seal. The external thread conforms to ISO standards, accepting standard washers and nuts, making it compatible with global plumbing practices.

Veteran plumbers who once doubted plastic now praise its consistency. “I’ve seen cast iron fail in ten years,” says one contractor in Berlin, “but my first PPR job from 2008 still runs flawless. That union fitting? It’s forgotten because it never gives trouble.”

Time Is the Ultimate Judge: Built to Last Beyond Decades

Accelerated aging tests show PPR systems maintaining integrity after 50 years at continuous 70°C operation—equivalent to over 10,000 days of real-world use. Independent labs confirm burst pressures exceeding 22 bar, far beyond typical household requirements. To ensure you’re getting genuine quality, look for clear mold markings, uniform wall thickness, and certifications like ISO 15874 or WRAS approval. Avoid opaque or flimsy fittings—they may cut costs today but cost more tomorrow.

To maximize lifespan, flush lines before commissioning and insulate outdoor sections. Even minor precautions extend service life, turning a robust solution into a lifelong asset.

More Than a Connection: An Investment in Future-Ready Infrastructure

As green buildings rise and smart water management gains traction, foundational choices matter. PPR is fully recyclable, requires less energy to produce than metal, and reduces leakage rates—key metrics in LEED and BREEAM evaluations. When integrated into metered or sensor-equipped networks, stable, non-leaking joints provide accurate data for predictive maintenance and conservation analytics.

The humble Transition Male Union may not flash on dashboards, but it supports everything above it. In an era where sustainability and resilience define excellence, choosing the right fitting isn’t just practical—it’s visionary.